The Analog Problem: Why Traditional Scales Fall Short

Analog scales use mechanical components that create serious problems for modern poultry operations:

Accuracy Issues: Mechanical components wear down over time, leading to increasingly inaccurate readings. Temperature fluctuations and vibrations affect calibration. When feed conversion calculations depend on precise measurements, even small errors compound into significant financial losses.

Human Error Factor: Operators must manually read and record data, introducing multiple error opportunities. Studies show manual data entry errors occur in up to 4% of all transactions, severely impacting flock management decisions.

Limited Functionality: Analog scales provide only basic weight readings without calculating essential statistics like average weight, uniformity coefficients, or growth rates.

Digital Revolution: The Modern Poultry Scale Advantage

Digital technology transforms poultry weighing into a comprehensive data management system offering superior accuracy, automatic recording, and advanced statistical capabilities.

Precision Engineering: Digital chicken scales use load cells delivering consistent accuracy within one gram. Unlike analog mechanisms, digital systems maintain calibration over extended periods and resist environmental factors.

Automatic Data Recording: Digital scales eliminate human error by automatically recording every measurement with timestamps, creating permanent, tamper-proof records.

Advanced Statistics: Modern digital scales calculate essential metrics automatically – average weights, uniformity percentages, coefficient of variation, and growth rates appear instantly.

Digital Weighing Methods: Manual and Automatic Systems

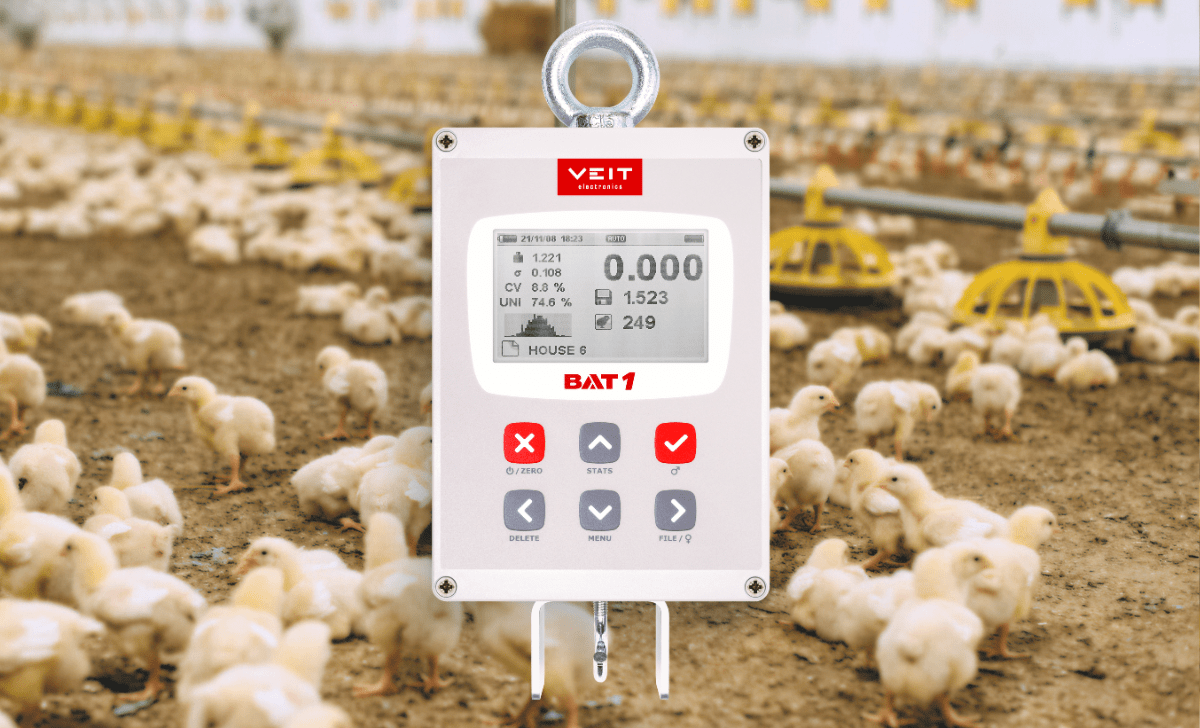

Manual Digital Scales: Like the BAT1, these require individual bird handling but provide essential opportunities for visual health assessments and detailed examination.

Automatic Digital Scales: The BAT2 Connect exemplifies continuous monitoring technology. Birds simply step onto weighing platforms during normal activities, eliminating handling stress while generating continuous data streams. These automated scale systems monitor flock development 24/7, capturing weight data from hundreds of birds daily without human intervention.

The Power of Automatic Weighing Systems

Automated systems provide unique advantages:

Continuous Monitoring: Daily insight into flock development enables early problem detection. Research shows early intervention based on continuous weight data can improve feed conversion ratios by 3-5%.

Reduced Handling Stress: Birds weigh themselves naturally during feeding activities.

Integration Capabilities: The BAT2 Connect integrates seamlessly with farm management systems through WiFi, cellular, and API connections.

Enhanced Data Volume: Automatic systems can weigh thousands of birds weekly versus 100-200 with manual weighing.

Real-World Performance Comparison

Field studies reveal dramatic differences in accuracy when examining the performance of various weighing setups. Analog scales showed accuracy variations of up to 15 grams under ideal conditions, while digital systems consistently delivered accuracy within one gram.

Operations using digital poultry weighing scale systems report improved feed conversion ratios and processing optimization through precise scheduling to hit target weights consistently.

The Financial Case for Digital Technology

Digital systems provide measurable returns through:

Accuracy-Driven Savings: Precise feed allocation reduces waste while optimizing growth rates

Data Quality Benefits: Consistent data enables better long-term planning

Risk Reduction: Early detection prevents losses that far exceed equipment costs

Making the Right Choice

The evidence overwhelmingly favors digital solutions. Modern poultry operations benefit from comprehensive strategies combining manual and automatic digital systems. Manual weighing provides detailed assessments while automated systems like the BAT2 Connect deliver continuous monitoring and real-time data access.

Digital technology delivers the precision needed for competitive poultry production. When profit margins depend on precise flock management, investing in proven digital poultry weighing technology pays dividends that far exceed initial costs.

Ready to transform your poultry weighing accuracy? Discover how the BAT2 Connect automatic scale can optimize your flock management at poultryscales.com/bat2connect.

Cited Sources

Hughes, R.J. and S.J. Wilkinson (2019). Flock Uniformity and Sample Size Requirements for Accurate Prediction of Live Weight During Mixed-Sex Rearing of Chickens. 30th Annual Australian Poultry Science Symposium.

Vasdal, G., Granquist, E. G., Skjerve, E., de Jong, I. C., Berg, C., Michel, V., & Moe, R. O. (2019). Associations between carcass weight uniformity and production measures on farm and at slaughter in commercial broiler flocks. Poultry science, 98(10), 4261-4268.