Modern poultry processing quality assurance begins with accurate weight monitoring. Research shows that weight uniformity directly impacts meat quality from farm to consumer (Petracci et al., 2022). Understanding this connection helps processors optimize efficiency while delivering superior products.

Weight Uniformity Drives Processing Excellence

Automatic poultry weighing systems ensure the consistent flock development critical for poultry meat processing and quality. Studies demonstrate that flocks with coefficient of variation below 8% achieve optimal processing line performance (Manning et al., 2022). Weight variation above 12% CV creates significant processing challenges, with poorly managed flocks experiencing weight differences as extreme as 100% between lightest and heaviest birds.

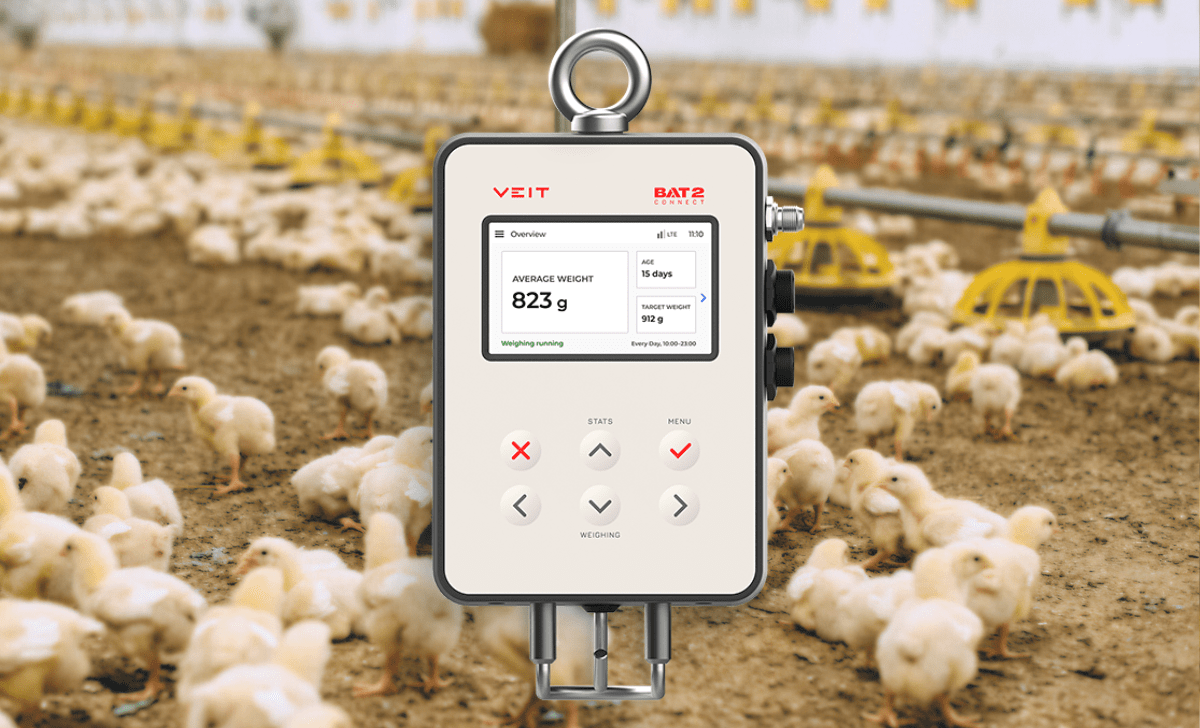

The BAT2 Connect automatic poultry scale addresses this challenge by providing real-time weight data integration with farm management systems. This connectivity enables immediate adjustments to feeding programs and environmental conditions when weight deviations occur.

Supply Chain Coordination Through Data

Poultry supply chain management software relies heavily on accurate weight predictions for processing scheduling. Castro et al. (2023) found that precision weighing technologies improve supply chain efficiency by 37% compared to traditional methods. Weight forecasting helps processors plan production schedules, minimize waste, and meet specific customer weight specifications.

Manual weighing with the BAT1 manual poultry scale provides essential backup data collection, especially in facilities transitioning to automated systems. The scale’s statistical capabilities calculate uniformity metrics instantly, supporting immediate decision-making and providing farmers with the peace of mind that they are hitting their targets.

Meat Quality Impact of Weight Management

Quality assurance in poultry processing depends on consistent carcass weights entering the processing line. Research indicates that weight uniformity affects deboning efficiency, with automated equipment performing optimally when processing similar-sized birds (Freick et al., 2022). Inconsistent weights reduce processing yields, decrease product quality, and increase labor costs.

Processing plants now separate birds by weight categories to optimize line efficiency. Poultry weighing systems enable this segregation by providing accurate weight distributions before slaughter.

Modern poultry weighing scale technology transforms raw weight data into actionable insights. Integrated systems track growth curves, predict final weights, and alert managers to potential issues before they impact meat quality and lead to penalties at slaughter. This proactive approach safeguards farmer profits, consistent product specifications and maintains customer satisfaction throughout the supply chain.

Cited Resources:

Petracci, M., Soglia, F., & Berri, C. (2022). Quality and processability of modern poultry meat. Animals, 12(20), 2766. https://doi.org/10.3390/ani12202766

Manning, L., Baines, R., & Chadd, S. (2022). Benchmarking the poultry meat supply chain. Benchmarking: An International Journal, 15(2), 148-165. https://doi.org/10.1108/14635770810864866

Castro, F.L.S., et al. (2023). Poultry industry paradigms: connecting the dots. Journal of Applied Poultry Research, 32(2), 100310. https://doi.org/10.1016/j.japr.2022.100310

Freick, M., et al. (2022). Incubation characteristics, growth performance, carcass characteristics and meat quality of Saxonian Chicken and German Langshan bantam breeds. Veterinary Medicine and Science, 8(4), 1578-1593. https://doi.org/10.1002/vms3.815