Every poultry weighing scale owner faces this nightmare. You walk into your poultry house, check your scale, and the numbers make no sense. Yesterday your birds averaged 2.5 pounds. Today the same birds show 0.3 pounds or 5 pounds.

Don’t panic. Most scale problems have simple fixes. Here are the five most common causes of crazy readings and how to solve them.

Problem 1: Birds Won’t Stay Still

Moving birds can be the biggest headache for any poultry scale. When chickens flap, jump, or shift weight, your traditional scales struggle with this movement and can’t get accurate readings.

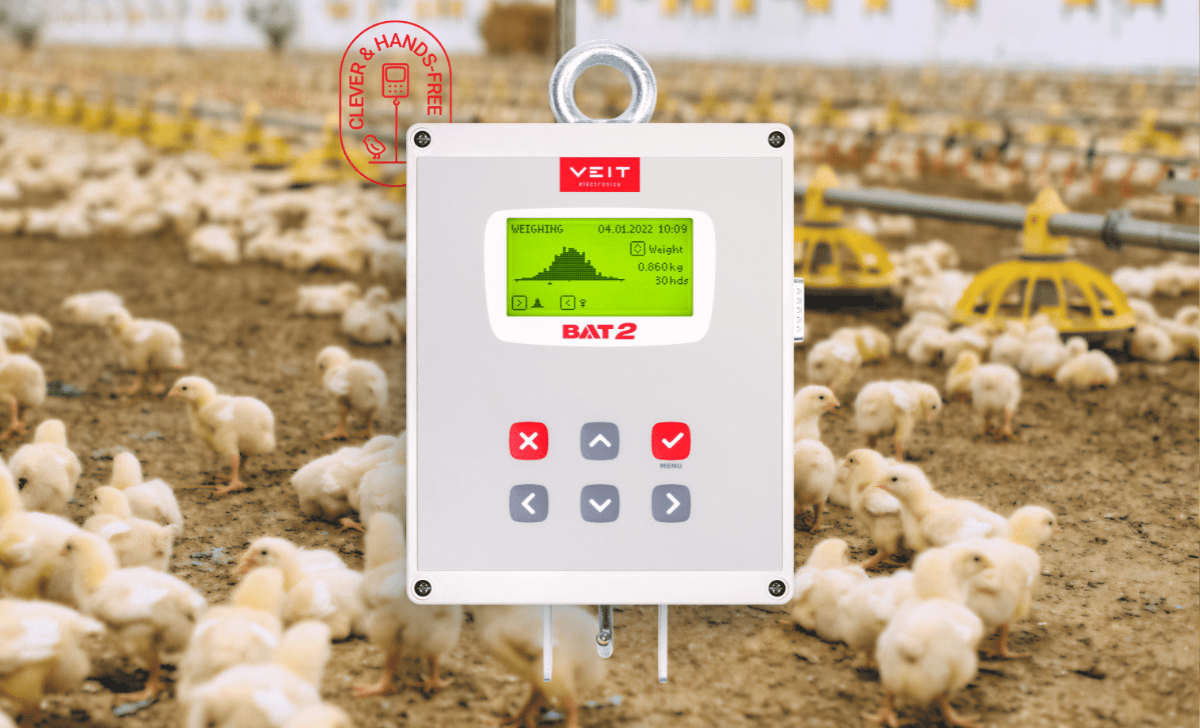

The fix: Modern automatic scales like the BAT2 use special algorithms to account for bird movement. These systems wait for the bird to settle and calculate the true weight even when birds move around.

For manual weighing, create a calm environment. Weigh birds at the same time each day when they’re naturally quieter. To get optimum results, you can also use a BAT1 manual poultry scale which is also specially designed to weigh live, moving birds.

Problem 2: Dirt and Droppings Build Up

Poultry houses are messy places. Feathers, droppings, and litter stick to scale platforms. Even small amounts of debris can throw off your readings by several ounces.

The fix: Clean your scale platform daily. The BAT2 automatically compensates for gradual buildup between cleanings. This keeps your data accurate even in dirty conditions.

For small scale poultry flock owners using manual scales, wipe the platform before each weighing session.

Problem 3: Uneven Platform Placement

Floor-mounted scales only work when perfectly level. Uneven ground, settling foundations, or debris under the scale create false readings. This affects both large-scale poultry farming operations and backyard flocks.

The fix: The BAT2 hangs from the ceiling, eliminating ground-level problems entirely. Suspended scales stay level automatically and avoid floor contamination.

If you use floor scales, check the level weekly. Place scales on solid, even surfaces in high-traffic areas, such as between feed and water dispensers.

Problem 4: Wrong Calibration Settings

Scales drift over time. Temperature changes, vibrations, and normal wear affect accuracy. Many poultry feed bin scales and weighing systems lose calibration without obvious signs.

The fix: Calibrate your scales monthly using known weights. Professional poultry weighing scale systems like the BAT2 have clear, easy-to-use calibration features to help you maintain accuracy longer.

Never skip calibration checks, especially in large-scale poultry house designs where accurate data drives major decisions.

Problem 5: Environmental Interference

Vibrations from fans, footsteps, or machinery can fool your scale’s sensors. Wind, temperature swings, and electrical interference also cause problems.

The fix: Position scales away from fans and other disruptive equipment. The BAT2‚s hanging design reduces vibration transfer from the ground. Its advanced sensors filter out environmental noise.

For small scale poultry processing equipment setups, create a dedicated weighing area away from other machinery.

Prevention Is Better Than Repair

Regular maintenance prevents most scale problems:

– Keep platforms clean

– Check calibration monthly

– Inspect cables and connections regularly

– Monitor data for unusual patterns

– Keep spare parts on hand

Modern automatic systems like the BAT2 require very little maintenance, but basic care still matters.

When to Upgrade Your System

If you’re constantly fighting scale problems, consider upgrading. The BAT2 Automatic Poultry Scale solves the most common issues with:

– Movement compensation algorithms

– Automatic debris adjustment

– Ceiling-mounted design

– Self-calibration features

– Real-time data integration

Whether you manage the small scale poultry flock or run industrial operations, reliable weight data drives better decisions and higher profits.

Stop wasting time on faulty readings. Fix these common problems and get back to growing healthy, profitable birds.