When implementing a weighing system into poultry farms, it is important to clearly establish why weighing is important. Regardless of the type of poultry being weighed, the primary goal of any weighing system is to provide an accurate picture of current flock development. An effective system offers a key advantage by enabling breeding decisions based on trustworthy and precise data. The decisions vary depending on the type of poultry being raised, but the significance of accurate weighing is well captured in the conclusion of the Cobb Breeder Management Guide: „Accurate feed amounts can only be determined if the bodyweight is measured accurately.“ (1)

Similar importance is attributed to weighing in the Management Handbook by ROSS, produced by Aviagen. This handbook describes the management of poultry development based on accurate estimations of average weight and CV/uniformity in each population. (2)

Conversely, inaccurate weighing, poor weighing practices, or distortion of weight data due to human errors such as cheating can lead to overfeeding or underfeeding. This deviation from the optimal recommended growth curve can result in a drop of more than 10–15 eggs in parent flocks of meat-type poultry. (3)

For broiler production, precise weighing allows for accurate monitoring of average weight, growth rates, CV, and uniformity. Proper management based on current and accurate weight data can lead to excellent feed conversion ratios. A highly uniform flock makes it possible to achieve desired processing weights and avoid penalties. Additionally, a weighing system capable of early detection of emerging illnesses within the flock enables timely responses and the mitigation of negative impact on production.

Types of Weighing Equipment

In general, there are three types of weighing equipment. The first comprises mechanical and digital scales not specifically designed for poultry. These are often used in smaller operations due to their low cost. However, this initial cost advantage is very quickly nullified by expensive mistakes stemming from management decisions made based on consequently inaccurate weight data outputs, such as those arising from cheating.

The second type consists of specialised manual electronic scales designed for poultry use. These scales simplify and expedite the weighing process, reduce labour needs, eliminate the potential for cheating, and provide accurate and reliable data. They also allow for direct interaction with the birds, allowing for the assessment of body structure. More advanced scales, such as the well-known BAT1, offer features such as fleshing score.

The third type includes fully automatic scales that can perform automated weighing, either continuously or at scheduled intervals. Equipped with weighing platforms, these scales allow birds to step onto them without human intervention. When fully integrated into farm management software, these scales can provide access to real-time weight data from multiple locations. Automatic scales are often supplemented by electronic manual scales for re-weighing birds at set intervals or after detecting deviations from the recommended growth curve. This approach disturbs the developing birds less, reducing stress levels and risk of disease.

A fundamental overview of weighing methods and their individual benefits can be found on a specialised website dedicated to poultry weighing: https://poultryscales.com/waystoweigh. (4)

Recommendations for Proper Weighing from Leading Poultry Companies

Manual weighing of poultry should occur weekly at the same time and ideally with the same interval from the last feeding in the case of parent flocks. (5)

Weighing should take place at a minimum of three locations within the house (or pen). (6) Each sample should represent 2% of the population or at least 50–100 birds. (7) To create a sample, a catching pen should be used that allows chicks to enter it freely. Samples should be collected closer to the longitudinal axis of the facility, avoiding areas near the edges and entrances.

Aviagen also recommends the practice of „bulk weighing,“ wherein multiple birds are weighed simultaneously using a container. This method is recommended during the first 14 days of the flock’s age. (8) After 14 days, individual weighing is advised. (9) It is generally agreed that proper calibration of scales and using the same scale for repeated weighing sessions are crucial.

The main distinction of automatic weighing lies in having scales present throughout the facility or pen during the entire rearing process. When the scale is installed correctly, according to Cobb’s management guide, an average of 100 female birds will step on it per hour. (10) The number of weighings is usually significantly higher than in manual weighing, allowing for continuous or interval-based monitoring. Integrating such scales directly into farm management systems makes all current statistics and individual weight values instantly available. Automatic scales are ideal for house-based production, where one weighing platform per 500 m2 is sufficient when positioned close to the centre between the feeding and watering systems. (11) This approach also suits box-based production, where multi-platform solutions can be utilised.

An important advantage of automatic weighing, as highlighted by Cobb, is the ability to quickly respond to deviations from the standard, which can indicate potential feeding equipment or distribution issues. Furthermore, the data is more consistent compared to manual weighing, and less labour is required, providing benefits in terms of biosecurity and labour costs. (12)

Optimal Implementation and Configuration of Weighing System

A turning point for modern poultry farm management came with the introduction of manual electronic scales with internal data recording and subsequent export to farm management software. Comparing farms using non-specialized scales for poultry weighing to those using specialised electronic scales consistently demonstrates better results in the latter. One confirmation of this is Japfa Indonesia’s recent transition to BAT1 electronic manual scales throughout their entire operation, currently operating over 400 units. (13)

The implementation of an automatic weighing system further allows continuous access to real-time flock development data, enabling immediate response to any deviations from the optimal state. Additionally, it reduces the labour demand for flock management. An optimal solution is a combination of automatic weighing systems, providing instant insights into flock development, and manual weighing, conducted at predetermined intervals or immediately upon detecting deviations from the recommended growth curve.

Data from both systems should be directly integrated into the main farm management software of each farm, ensuring that all data is consistently available in one place. Such comprehensive solutions and integration options with any farm management software are offered by VEIT Electronics‘ BAT scales.

Recommendations for Proper Handling of Weight Data

There are two general recommendations for effectively working with bird weight data. First, data should always be reliable as it fundamentally affects all subsequent decisions and, ultimately, flock performance. Second, it is optimal for all data, including weight data, to be continuously available in one place. This provides a complete overview of farm operations and establishes the basis for truly effective management.

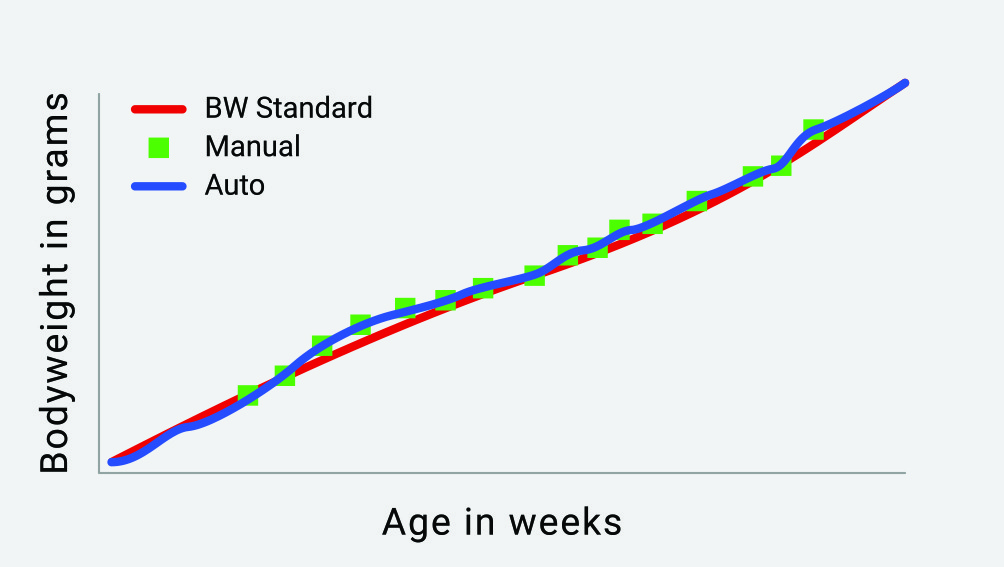

The key values that need to be monitored include average weight, and these values from both automatic and manual weighing sessions should be recorded and graphically displayed together. This enables the analysis of deviations from the optimal growth curve and allows for the implementation of further actions.

In addition to the standard measurement of uniformity, it is also useful to monitor standard deviation and the coefficient of variation, which, despite its potential usefulness, is sometimes overlooked. The coefficient of variation can serve as an estimate of the number of individuals within a certain weight range. This is highly valuable, for example, when raising parent flock hens in relation to the decision on when to start extending the length of exposure to daylight. (14) For further analyses and decision-making, it is also valuable to have automatically calculated statistics on the number of weighings, average weight, daily gain, individual body weights, as well as histograms and displays of deviations from the recommended growth curve. All these statistics can be automatically calculated and exported to farm management software, for example, by BAT2 Connect and BAT1 scales.

- Cobb Breeder Management Guide. Page 75.

- Ross Parent stock Management Handbook 2018. Page 81.

- Vážení kuřic a slepic rodičovského hejna masného typu slepic (Weighing Broiler Breeder Hens (Meat-Type)). Drůbežář 2009. Page 6-7.

- poultryscales.com: Fast, precise weighing for reliable data you can access and use from anywhere. https://poultryscales.com

- Vážení kuřic a slepic rodičovského hejna masného typu slepic (Weighing Broiler Breeder Hens (Meat-Type)). Drůbežář 2009. Page 6-7.

- Hubbard Breeder Management Manual. Page 9.

- Aviagen: How To… Individually Weigh Broiler Breeders in Rear. Page 03.

- Aviagen: How To… Bulk Weigh Broiler Breeders in Rear. Page 04.

- Aviagen: How To… Individually Weigh Broiler Breeders in Rear. Page 01.

- Cobb Breeder Management Guide. Page 76.

- Veit.cz: Poultry scales for professionals. https://www.veit.cz/

- Cobb Breeder Management Guide. Page 77.

- Linkedin VEIT Electronics: 400+ BAT1 scales now on site at JAPFA farms. https://www.linkedin.com/feed/update/urn:li:activity:7039663635563970560

- Vyrovnanost rodičovských hejn masného typu (Uniformity of Parent Flocks (Meat-Type)). Drůbežář 2009. Page 12-13.