Achieving consistent breeder performance in poultry farming is paramount for maintaining optimal productivity and profitability. A central challenge to this goal is minimizing feeding discrepancies to ensure uniform growth across the flock. One viable solution is to transition from conventional weekly feed calculations to establishing a comprehensive feeding curve tailored to the entire rearing duration and local environmental variables.

As the use of sorting pens becomes less common, adherence to a standardized feeding regimen becomes imperative. This requires the adoption of automated feeding and computing systems, ideally initiated by day 8 of the rearing process. These sophisticated systems enable the input of a meticulously crafted feeding curve into a computerized platform, facilitating precise feed calculations while accounting for variables such as mortality rates and culls as entered by the operator.

Nevertheless, it is vital to underscore that while automation enhances efficiency, effective farm management and optimal environmental conditions remain indispensable for success, including sufficient feeder and drinker space, as well as proper ventilation to uphold air quality and dry litter conditions.

Growth curves and feed increases

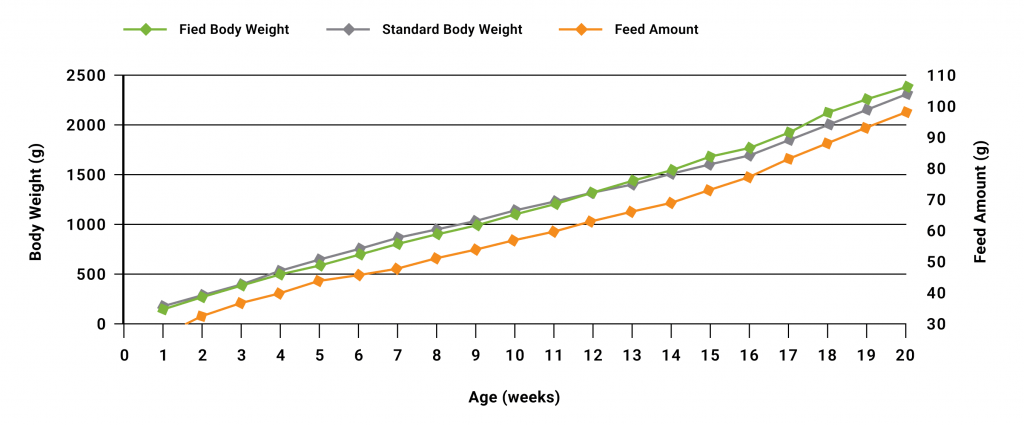

Integral to implementing an established feeding curve is maintaining the average body weight and flock uniformity within defined ranges, typically 98% to 102% of standard body weight and above 68% for flock uniformity. Reliable automatic scales play a pivotal role in this process, providing accurate daily bodyweight measurements and facilitating effective weight tracking to ensure adherence to desired standards. By leveraging automated and computerized feed calculations alongside automatic scales, human error is minimized, resulting in a more consistent breeding program and ultimately yielding prepared pullets at the desired condition for transfer, typically around 20 to 22 weeks of age.

Overall, the main goal of rearing is to achieve the desired uniformity through consistent bird growth while also minimizing stress. Best practices show a minimum feed increase of 2 g/week is most effective in reaching these goals. Here is a short list of additional guidelines to follow:

- Ensure 7-day bodyweight is on target and strictly control bodyweight from 2 to 4 weeks.

- From 4 to 10 weeks of age, it is better to be below the standard bodyweight rather than over it. This ensures the effectiveness of relatively uniform (2 to 3 g) feed increases until 12 weeks of age, at which point, the average bodyweight should be on target. Planning for substandard weights during this time also prevents the birds from developing overtly large frames that will require more feed to maintain during production.

- From 12 to 20 weeks of age, aiming slightly above the target body weight enhances fat deposition, facilitating earlier production onset.

An example of weight data collected while using this method of rearing.

Graph of collected data in comparison with recommended growth curve.

Despite the benefits conferred by automation, vigilant oversight by farm caretakers remains paramount to ensure the seamless operation of feeding and weighing systems. Additionally, the accuracy of feed specifications must be verified to mitigate potential issues arising from inaccuracies, emphasizing the importance of adhering to established recommendations.

Automatic vs. Manual Weighing

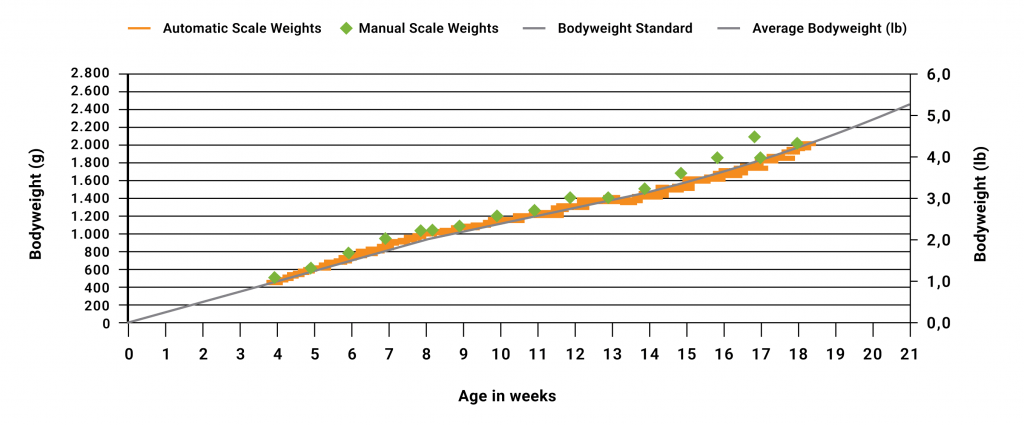

In assessing weighing methodologies, the efficacy of automatic scales versus manual weighing warrants attention. While automatic scales offer cost savings and efficiency benefits, manual weighing may yield comparable results depending on sample size and weight range. However, maintaining consistency in weighing practices is imperative to ensure data accuracy, particularly as production progresses and variations between manual and automatic weighing methods become more pronounced.

When weighing manually, it is imperative to maintain consistency in terms of weighing practices. The graph below demonstrates the risk of failing to do so. In this example, farmers moved the weighing location closer to a large feed hopper, where heavier birds are naturally more prevalent. This change distorts the data collected, giving the impression that the flock is significantly overweight.

Uniformity Above All

Uniformity management is paramount in breeder rearing, especially in the absence of grading pens. The initial 8 weeks of rearing are critical for frame development and fostering uniformity, underscoring the importance of small bird recovery during this period. Grading or sorting small flock members at around 4 weeks of age and ensuring timely recovery by 6 to 7 weeks are instrumental in maintaining uniformity. This principle applies to both male and female birds, with early grading recommended under specific conditions to address uniformity challenges effectively.

Moving Forward

As the landscape of poultry farming evolves, marked by labor shortages, increased reliance on mechanical devices and automation has become commonplace to streamline operations. While these innovations confer enhanced consistency in flock performance, ensuring proper equipment control and maintenance remains paramount. Farm staff must receive comprehensive technical training to proficiently manage automated systems and validate data accuracy, safeguarding the reliability of flock management practices.

In conclusion, achieving consistent breeder performance in poultry rearing necessitates a multifaceted approach encompassing strategic feeding practices, diligent weight management, and meticulous uniformity maintenance. By leveraging automation alongside meticulous oversight and technical expertise, poultry farmers can optimize breeding programs and enhance overall flock performance.