Every successful poultry operation depends on accurate weight monitoring. Manual weighing provides essential hands-on assessment that no farmer should eliminate. But here’s the challenge: daily manual weighing simply isn’t economically feasible for most operations.

This creates a dangerous gap in monitoring. Problems can develop and compound between weekly manual weighing sessions, costing thousands in lost performance before detection.

Smart farmers have found the solution. Automatic poultry scales bridge this monitoring gap, providing continuous data collection that complements essential manual weighing programs.

The Economic Reality of Daily Monitoring

Manual weighing remains the gold standard for detailed flock assessment. Experienced farmers rely on hands-on evaluation to assess body condition, detect health issues, and make critical management decisions. This direct contact with birds provides insights that no automated system can match.

However, the economics of daily manual weighing create impossible challenges:

A typical manual weighing session requires significant labor investment. For comprehensive daily monitoring across multiple houses, operations would need substantial daily labor just for weighing. This level of labor investment makes daily manual weighing impractical for most farms.

Weekly manual weighing represents the practical limit. Yet daily weight changes provide critical early warning signals. Disease outbreaks, feed issues, and environmental problems all show up in daily weight patterns before becoming visible problems. The growth rate of chickens serves as a sensitive indicator of discomfort in a flock, making real-time, accurate measurement essential for early identification of problems.

This monitoring gap puts profits at risk. Small issues that could be caught and corrected with daily data become major problems by the next weekly weighing session.

How Automated Scales Fill the Monitoring Gap

An automated scale operates continuously between manual weighing sessions without additional labor costs. The most accurate smart scale systems provide 24/7 monitoring that captures the daily data manual weighing cannot economically deliver.

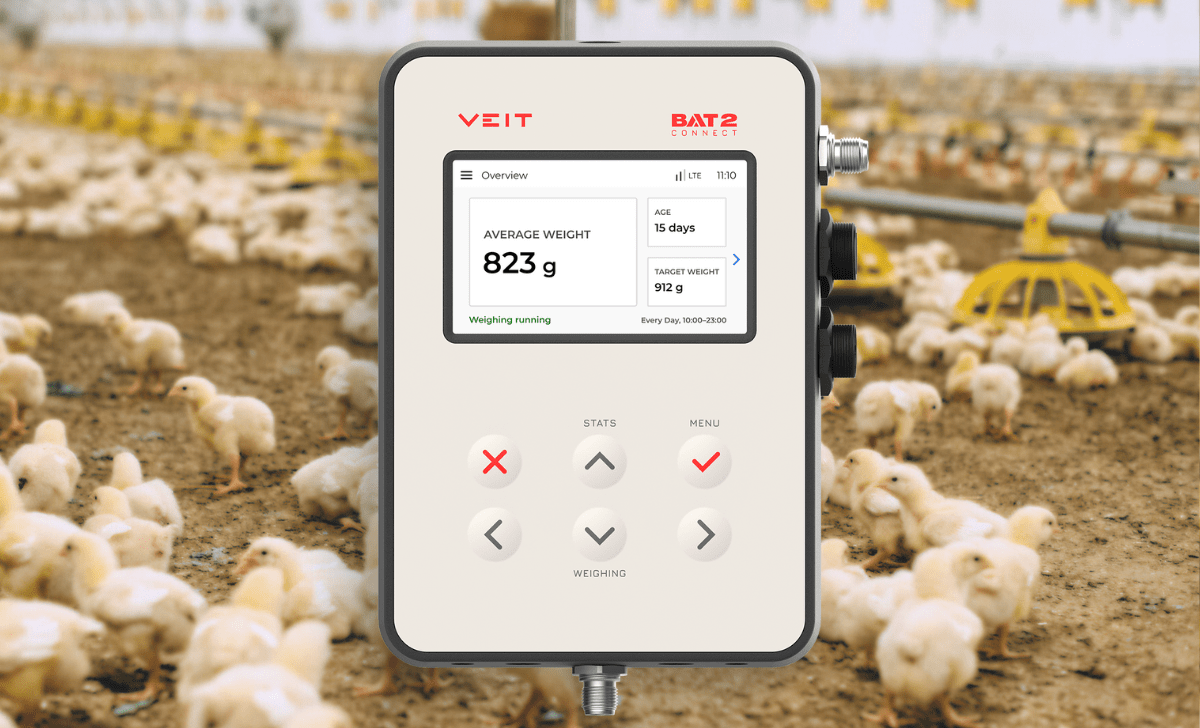

BAT2 automatic poultry scales provide an effective solution. Birds step onto the weighing platform naturally during their normal activities. The system records each weight automatically, building a comprehensive database of daily performance trends.

This continuous monitoring creates several advantages:

Enhanced Detection: Automated systems catch problems between manual sessions, preventing small issues from becoming major losses.

Stress Reduction: Birds aren’t handled daily, reducing stress while maintaining comprehensive monitoring.

Labor Efficiency: Daily data collection happens automatically, freeing workers for other essential tasks.

Data Completeness: The information gap between manual weighing sessions disappears.

The Perfect Partnership: Manual and Automatic Systems

The most successful operations combine both weighing methods strategically. Manual weighing provides detailed assessment that automated systems cannot match. Automatic scales provide daily monitoring that manual weighing cannot economically deliver.

Research from leading poultry companies confirms this approach. An optimal solution combines automatic weighing systems, providing instant insights into flock development, and manual weighing, conducted at predetermined intervals or immediately upon detecting deviations from expected performance.

Real-World Efficiency Gains

Operations implementing automated scales alongside manual weighing programs report significant efficiency improvements. Electronic scales provide the shortest path to accurate daily weighing data and the resulting savings generated by responsive poultry farming.

Labor Optimization: Instead of impossible daily manual weighing, automated systems optimize when manual weighing occurs. Automated alerts trigger targeted manual assessments only when necessary.

Feed Conversion Improvements: Daily weight monitoring enables precise feed adjustments. Research shows proper feed management based on accurate weight data can improve feed conversion ratios significantly.

Disease Detection Speed: Automated systems detect performance drops within 24-48 hours. Early intervention prevents disease spread and minimizes flock impact.

Mortality Reduction: Continuous monitoring enables rapid response to health challenges, reducing mortality rates in many operations.

Technology That Complements Your Expertise

Modern poultry weighing scale technology enhances rather than replaces farmer expertise. The BAT2 Connect series of automatic scales integrates seamlessly with existing farm management systems, combining automated data with manual assessments.

Key features that improve farm efficiency include:

Automatic Calculations: Average weights, growth rates, and uniformity statistics calculate automatically, saving time and reducing errors.

Data Integration: Automated data combines with manual weighing records in farm management software, providing complete performance pictures.

Early Problem Detection Saves Money

The economic value of daily monitoring becomes clear during health challenges. Meta-analyses show that chickens infected with common diseases like coccidiosis experience reduced daily feed intake of 19g and decreased daily weight gain of 39g. The growth rate drops by 10.5% in affected birds (Freitas et al., 2023).

Automated scales detect these performance changes immediately. Early detection enables:

Rapid Intervention: Treatment begins within hours rather than days, limiting disease spread and impact.

Reduced Treatment Costs: Early intervention requires less medication and results in better outcomes.

Minimized Performance Loss: Quick response prevents minor issues from becoming major problems.

Improved Recovery: Birds treated early recover faster with less long-term impact.

Heat stress provides another example. Research shows heat-stressed chickens have decreased feed intake by 98g and reduced body weight gain by 151g (Liu et al., 2020). These changes appear in daily weight data before visual symptoms develop, enabling proactive management responses.

Choosing the Right Automated Scale

Not all poultry scale systems deliver equal results. The most effective systems combine accuracy, durability, and integration capabilities that enhance existing manual weighing programs.

Essential features include:

Precision Accuracy: Systems should maintain gram-level precision that matches manual scale accuracy for consistent data across both methods.

Seamless Integration: Look for systems that combine automated and manual data in existing farm management software.

Reliable Operation: Equipment must handle poultry house environments without performance degradation.

User-Friendly Interface: Systems should be easy to operate and maintain without extensive technical training.

Data Export Capabilities: Automated data should transfer easily to management software and reporting systems.

Implementation Strategy

Successful implementation enhances existing manual weighing programs rather than replacing them. Strategic planning ensures maximum benefit from both weighing methods.

Location Selection: Position automated scales in high-traffic areas where birds pass naturally. Avoid locations near feed or water systems where behavior patterns might skew data.

Calibration Consistency: Maintain calibration standards across both manual and automated systems to ensure data compatibility.

Staff Training: Train team members to interpret combined data streams and respond appropriately to automated alerts.

Validation Protocols: Establish procedures for validating automated data with periodic manual weighing comparisons.

Getting Started

Implementing automated weighing begins with evaluating current monitoring practices and identifying gaps in daily data collection. Calculate the cost of problems that could be prevented with earlier detection.

The BAT2 automatic poultry scale represents proven technology that thousands of operations worldwide use to complement their manual weighing programs. This system provides the daily monitoring data that manual weighing cannot economically deliver while supporting the hands-on assessment that experienced farmers require.

Consider your operation’s specific needs:

House Layout: How many locations need monitoring?

Flock Size: What sample size ensures representative data?

Management Software: How will automated data integrate with existing systems?

Staff Resources: Who will monitor automated data and respond to alerts?

The Future of Efficient Monitoring

Modern poultry farming demands both the expertise of experienced farmers and the efficiency of smart technology. Manual weighing provides essential hands-on assessment. Automated scales fill the economic gap in daily monitoring.

This combination delivers comprehensive flock monitoring that neither method can achieve alone. Daily data collection happens automatically while detailed assessment occurs through strategic manual weighing sessions.

Operations using this approach gain competitive advantages through better data, faster problem detection, and more efficient resource use. The question isn’t whether to choose manual or automated weighing, but how to combine both methods for maximum efficiency and profitability.

Contact weighing system specialists to evaluate how automated scales can complement your existing manual weighing program. The right combination of manual expertise and automated efficiency positions your operation for long-term success in an increasingly competitive industry.

Cited Sources

Freitas, L. F. V. B., Sakomura, N. K., Reis, M. P., Mariani, A. B., Lambert, W., Andretta, I., & Létourneau-Montminy, M. P. (2023). Coccidiosis infection and growth performance of broilers in experimental trials: insights from a meta-analysis including modulating factors. Poultry Science, 102(11), 103021.

Liu, L., Ren, M., Ren, K., Jin, Y., & Yan, M. (2020). Heat stress impacts on broiler performance: a systematic review and meta-analysis. Poultry Science, 99(11), 6205–6211.