When chicken growth is suboptimal, farmers are inclined to investigate the underlying causes. One effective approach is comparing current growth performance data with historical records to identify recurring patterns. Chicken growth is influenced by numerous factors during the fattening period, but factors from the parent flock and hatchery stages also play a significant role. Seasonal variations are well-documented influences on growth, and discrepancies in growth may reflect physiological responses to different times of the year. Comparing growth data across flocks, parent flocks, hatcheries, environmental conditions, and weather patterns can provide farmers with critical insights into the factors affecting growth.

The importance of recording growth data was underscored by Van Limbergen et al. (2020), who evaluated factors influencing the European Production Index (EPI) during the fattening period. Their study showed that farmers who compared their flock performance data—such as body weight, feed intake, and water consumption—with previous batches or standardized schemes achieved significantly higher EPI scores than those who did not. This comparison allows for more accurate adjustments between production cycles, ultimately enhancing farm productivity. Effective data management is, therefore, an indispensable component of modern poultry flock management.

Factors Influencing Chicken Growth: Insights from Data Analysis

Discrepancies in chicken growth may result from a wide range of factors, such as suboptimal housing conditions or changes in feeding practices. However, analyzing historical data can reveal recurring growth patterns over time, allowing farmers to identify potential causes across different stages of the production cycle. Data collected from breeder farms (e.g., flock age, egg production, egg weight, growth performance, mortality), hatcheries (e.g., hatchability, egg storage time, temperatures), and slaughter plants (e.g., carcass uniformity, carcass condemnation percentage, weight uniformity, food pad dermatitis score) offer a rich source of information to better understand growth variations (Iqbal et al., 2017; Melo et al., 2021; Junghans et al., 2022).

De Jong and van Riel (2020) conducted a six-year field study to evaluate the impact of various factors on broiler growth performance. Data from 2,174 broiler flocks across 74 broiler farms were linked to 88 broiler breeder farms and 209 breeder flocks. The researchers identified significant correlations between broiler growth and various parameters, such as the age of the parent flock. For instance, as the age of the parent stock increases, the weight of hatching eggs rises, resulting in larger chicks with enhanced growth potential and quicker attainment of slaughter weight (Nangsuay et al., 2011; Jacobs et al., 2017).

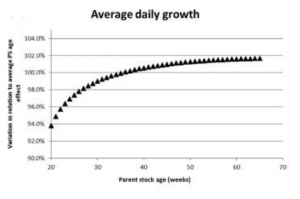

Figure 1. The Impact of Parent Stock Age on Offspring Growth. The horizontal axis in Figure 1 represents the age of the parent stock in weeks, while the Y-axis displays the variation in relation to the average parent stock age effect, set at 100%. PS: Parent Stock (De Jong and van Riel, 2020).

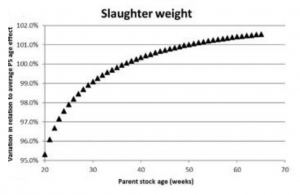

As depicted in Figure 1, an increase in parent stock age is clearly associated with improved growth in their offspring. This can be explained by the corresponding increase in hatching egg weight as the parent flock ages (Nangsuay et al., 2011). Heavier eggs result in larger chicks, which exhibit enhanced growth potential and achieve slaughter weight more quickly (Jacobs et al., 2017). Therefore, slaughter weight is also significantly correlated with parent stock age, as shown in Figure 2.

Figure 2. The Effect of Parent Stock Age on Offspring Slaughter Weight. The X-axis in Figure 2 represents parent stock age in weeks, and the Y-axis shows the variation relative to the average parent stock age effect, set at 100%. PS: Parent Stock (De Jong and van Riel, 2020).

Another key factor influencing production is seasonal effect. Junghans et al. (2022) analyzed data from six barns in Germany, covering 107 fattening periods between January 2019 and June 2020. The seasons were classified as follows: winter (December–February), spring (March–May), summer (June–August), and fall (September–November). Across all flocks, the average broiler weight at the end of fattening was 2.30 kg. The heaviest birds were observed in the fall (mean weight of 2.38 kg), while the lightest were in the spring (2.27 kg).

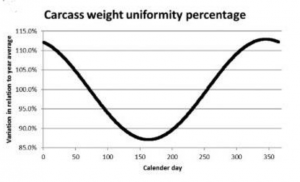

Furthermore, carcass weight uniformity is significantly affected by seasonal variations. De Jong and van Riel (2020) highlighted the impact of seasonality on carcass uniformity, as illustrated in Figure 3.

Figure 3. The Effect of Season on Carcass Weight Uniformity. The X-axis in Figure 3 represents the day of the year when day-old chickens were housed, and the Y-axis indicates the variation in relation to the annual average, set at 100% (De Jong and van Riel, 2020).

Carcass weight uniformity was highest in chicks housed during the middle of the year. Day-old chicks placed in barns during the summer months, when temperatures are higher, experience more favorable conditions at the start of the fattening period, resulting in lower mortality rates and better flock health, which in turn contribute to higher uniformity (Vasdal et al., 2019).

Junghans et al. (2022) identified additional factors influencing growth, such as antibiotic use, flock size, and stocking density. Flocks that were not treated with antibiotics had a higher average weight (2.33 kg) compared to treated flocks (2.24 kg). Higher stocking densities (up to 39 kg/m²) were also associated with greater average weight. Additionally, smaller flocks (fewer than 11,000 birds) generally performed better, while the highest average weights were observed in flocks of 11,000 to 30,000 birds.

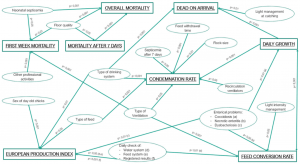

The interconnectivity of various factors influencing chicken meat production is significant, and understanding these interactions is crucial for farmers. Van Limbergen et al. (2020) conducted a comprehensive analysis of data from 2,309 flocks across 358 broiler farms in seven EU member states. They identified key risk factors affecting growth, feed conversion ratios, slaughter condemnation rates, early and overall mortality, and EPI.

Figure 4. Causal Pathways Between Key Factors in Broiler Farming. Figure 4 presents a graphical representation of the key factors that influence these parameters (Van Limbergen et al., 2020). The p-values indicate the strength of associations: P < 0.001 denotes a strong association, P < 0.01 indicates a moderate association, and P < 0.05 signifies the lowest level of statistical significance, but still significant.

The correlations identified through this data analysis provide valuable insights into different segments of the poultry production chain, allowing farmers to make informed decisions based on data.

Growth Performance Data as a Component of Poultry Management Systems

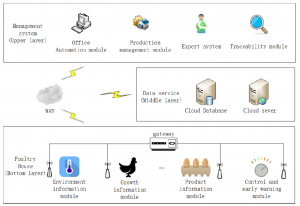

The rise of precision poultry farming has the potential to greatly enhance livestock management. By utilizing available data, poultry farming management systems can incorporate multiple functions, including personnel management, financial operations, and comprehensive information about flock health, environmental conditions, feed management, and growth performance. Zheng et al. (2021) developed a poultry management system that incorporates these elements to assist farmers in making informed decisions. The system’s overall configuration is shown in Figure 5.

The core component of the system is a cloud-based database, which serves as a repository for all growth performance data. Farmers using BAT1 and BAT2 poultry scales can utilize BAT Cloud, a secure database for storing growth data and comparing current flock performance with previous years. The bottom layer of the system aggregates data from the chickens, while the core focus is on ensuring accurate weighing, which is vital for profitability. Incorrect weight data can lead to poor decision-making and have detrimental effects on the flock.

To evaluate poultry growth effectively, it is advantageous to use scales that facilitate simple data acquisition. The BAT1 and BAT2 poultry scales allow data to be downloaded to a personal computer for evaluation, ensuring data accessibility and comparability across production cycles. As such, these scales can be easily integrated into poultry management systems.

Figure 5. Example of Possible Poultry Management System (Zheng et at. 2021).

The upper layer of the management system comprises four distinct modules. The production management module oversees temperature, humidity, air flow, and growth monitoring, along with other operational aspects of the poultry house. The office management module handles business-related tasks such as personnel management, finances, and invoicing. The expert system module employs AI techniques like data mining and machine learning to provide recommendations for settings adjustments based on discrepancies in growth. Lastly, the traceability module tracks all system processes, including feed and drug purchasing, transportation, and traceability data.

Intelligent sensors, a wireless sensor network, and a cloud database enhance the interaction between these modules, improving communication between farmers and their livestock. Concurrently, the system archives accumulated data in the cloud, with the information management system guiding the evolution of poultry farming practices.

Using Weighing Data for Growth Prediction

A significant amount of data can be used to forecast production parameters in poultry farming. Accurate predictions of growth outcomes help farmers estimate the slaughter weight of their chickens. Several models have been developed for this purpose. One such model, AVINESP, functions as a decision-support tool for both broilers and layers. It simulates the effects of nutritional changes, various feeding programs, health challenges, and environmental stressors on feed intake, live weight, and nutritional requirements (Hauschild et al., 2015). Another model, INAVI, simulates broiler growth under a range of nutritional and environmental conditions. The enhanced version, CENTRAVI, incorporates additional inputs such as dietary energy and amino acid content, particle size of the feed, temperature, humidity, air speed, and stocking density (Méda et al., 2015). However, the use of these systems is limited by the unpredictability of changes that may occur during the fattening process, which is why these prediction models are not widely employed in a systematic manner.

New approaches using machine learning techniques offer potential solutions for forecasting production parameters based on farm-generated poultry data. Sensor technologies are being increasingly adopted to provide real-time measurements of environmental conditions, such as temperature, humidity, and ventilation, as well as chicken-related parameters like behavior, feed intake, heat stress, disease, production, and growth (Astill et al., 2020). Artificial neural networks (ANNs) have been particularly useful for predicting various poultry performance metrics, including hatchability (Mehri, 2013), feed and water intake (Abreu et al., 2020), hatching egg production (You et al., 2021), carcass characteristics (Faridi et al., 2011), and growth, with a particular focus on predicting slaughter weight (Jahan et al., 2020).

In the context of weight prediction, Jahan et al. (2020) applied an artificial neural network to forecast the slaughter weight of meat-type quails. The input data included body weights at various stages—at hatch, as well as at five, ten, fifteen, and twenty days of age. The highest prediction accuracy was observed at 20 days, and the model’s accuracy was measured using the coefficient of determination, which ranges from 0 (no predictive power) to 1 (perfect prediction). The model predicted the weight at 45 days with a coefficient of determination of 0.9223, indicating a high level of accuracy. However, the primary limitation of these studies is that they are typically conducted in experimental conditions, where animals are kept in optimal environments. This minimizes the influence of stressors commonly encountered in commercial production settings. Consequently, the accuracy of prediction models is reduced when applied to real-world poultry farming due to the myriad factors influencing growth in commercial operations.

The advent of innovative technologies and sensor-based systems holds great promise for collecting comprehensive data across poultry production operations. Leveraging data analytics will enable farmers to make more informed decisions. Furthermore, automating farm procedures will increase the efficiency of poultry production systems. Automation also has the potential to improve animal welfare, enhance monitoring for infectious disease outbreaks, and offer greater transparency to consumers regarding poultry production processes.

Cited sources

Abreu, L. H., Yanagi Junior, T., Bahuti, M., Hernández-Julio, Y. F., & Ferraz, P. F. (2020). Artificial neural networks for prediction of physiological and productive variables of broilers. Engenharia agrícola, 40, 1-9.

Astill, J., Dara, R. A., Fraser, E. D., Roberts, B., & Sharif, S. (2020). Smart poultry management: Smart sensors, big data, and the internet of things. Computers and Electronics in Agriculture, 170, 105291.

de Jong, I. C., & van Riel, J. W. (2020). Relative contribution of production chain phases to health and performance of broiler chickens: a field study. Poultry science, 99(1), 179–188. https://doi.org/10.3382/ps/pez562

Faridi, A., Mottaghitalab, M., Darmani-Kuhi, H., France, J., & Ahmadi, H. (2011). Predicting carcass energy content and composition in broilers using the group method of data handling-type neural networks. The Journal of Agricultural Science, 149(2), 249-254.

Hauschild, L., Sakomura, N. K., & Silva, E. P. (2015). AvinespModel: predicting poultry growth, energy and amino acid requirements. In Nutritional modelling for pigs and poultry (pp. 188-207). Wallingford UK: CABI.

Iqbal, J., Mukhtar, N., Rehman, Z. U., Khan, S. H., Ahmad, T., Anjum, M. S., … & Umar, S. (2017). Effects of egg weight on the egg quality, chick quality, and broiler performance at the later stages of production (week 60) in broiler breeders. Journal of Applied Poultry Research, 26(2), 183-191.

Jacobs, L., Delezie, E., Duchateau, L., Goethals, K., Ampe, B., Buyse, J., & Tuyttens, F. A. M. (2017). Impact of transportation duration on stress responses in day-old chicks from young and old breeders. Research in veterinary science, 112, 172-176.

Jahan, M., Maghsoudi, A., Rokouei, M., & Faraji-Arough, H. (2020). Prediction and optimization of slaughter weight in meat-type quails using artificial neural network modeling. Poultry Science, 99(3), 1363-1368.

Junghans, A., Deseniß, L., & Louton, H. (2022). Data evaluation of broiler chicken rearing and slaughter—An exploratory study. Frontiers in Veterinary Science, 9, 957786.

Méda, B., Quentin, M., Lescoat, P., Picard, M., & Bouvarel, I. (2015). INAVI: a practical tool to study the influence of nutritional and environmental factors on broiler performance. In Nutritional modelling for pigs and poultry (pp. 106-124). Wallingford UK: Cabi.

Mehri, M. (2013). A comparison of neural network models, fuzzy logic, and multiple linear regression for prediction of hatchability. Poultry science, 92(4), 1138-1142.

Melo, E. F., Araújo, I. C. S., Triginelli, M. V., Castro, F. L. S., Baião, N. C., & Lara, L. J. C. (2021). Effect of egg storage duration and egg turning during storage on egg quality and hatching of broiler hatching eggs. Animal, 15(2), 100111.

Nangsuay, A., Ruangpanit, Y., Meijerhof, R., & Attamangkune, S. (2011). Yolk absorption and embryo development of small and large eggs originating from young and old breeder hens. Poultry Science, 90(11), 2648-2655.

Van Limbergen, T., Sarrazin, S., Chantziaras, I., Dewulf, J., Ducatelle, R., Kyriazakis, I., McMullin, P., Méndez, J., Niemi, J. K., Papasolomontos, S., Szeleszczuk, P., Van Erum, J., Maes, D., & PROHEALTH consortium (2020). Risk factors for poor health and performance in European broiler production systems. BMC veterinary research, 16(1), 287. https://doi.org/10.1186/s12917-020-02484-3

You, J., Lou, E., Afrouziyeh, M., Zukiwsky, N. M., & Zuidhof, M. J. (2021). Using an artificial neural network to predict the probability of oviposition events of precision-fed broiler breeder hens. Poultry Science, 100(8), 101187.

Zheng, H., Zhang, T., Fang, C., Zeng, J., & Yang, X. (2021). Design and Implementation of Poultry Farming Information Management System Based on Cloud Database. Animals : an open access journal from MDPI, 11(3), 900. https://doi.org/10.3390/ani11030900