Litter management represents one of the most critical factors in modern poultry production, wielding significant influence over bird health, welfare, and overall productivity. This bedding material—composed of both the initial substrate and accumulated fecal matter that covers commercial broiler house floors—serves essential functions in disease prevention by absorbing moisture from bird excrement and minimizing direct contact between birds and wet manure. When properly managed, litter creates a barrier that prevents infections and reduces reliance on antibiotics. However, poor litter management becomes a vector for economically devastating diseases such as coccidiosis, necrotic enteritis, and colibacillosis, facilitating their spread both within individual flocks and across production cycles. The consequences of inadequate management become particularly evident when litter moisture exceeds 25–35%, triggering a cascade of health problems that manifest as reduced weight gain, compromised feed conversion efficiency, and elevated mortality rates due to respiratory and systemic complications (Bolan et al., 2010).

Litter Material Selection and Economic Pressures

The foundation of effective litter management begins with material selection. Litter must fulfill multiple critical functions within broiler houses: preventing direct bird-to-floor contact, absorbing moisture from manure, urine, and feathers, and contributing to thermal regulation. Wood shavings have historically dominated as the preferred substrate in intensive poultry operations worldwide, earning their reputation through proven performance and availability. However, the industry now faces mounting economic pressures as wood shaving costs escalate dramatically due to increasing scarcity driven by poultry industry expansion and competition from other sectors. This economic reality has reached striking proportions—filling a standard Brazilian poultry house (120m × 12m with 10cm deep litter) now costs approximately $2,400 USD. Such substantial expenses have intensified the search for alternative litter materials, though research findings regarding their effects on broiler performance remain inconsistent.

The global diversity of litter materials reflects regional agricultural patterns, with farmers typically utilizing local plant byproducts from their area’s most cultivated crops. Sargeant et al. (2019) documented this worldwide variation, cataloging an extensive array of materials currently in use (Table 1).

Table 1. Various types of litter used worldwide (Sargeant et al., 2019).

Despite the variety of alternatives, comprehensive research by Toledo et al. (2019) reveals wood shavings‘ continued superiority in several key performance metrics:

– Alternative litter materials demonstrate no significant impact on broiler feed intake compared to wood shavings

– Wood shavings consistently produce statistically significant increases in broiler body weight relative to alternative materials

– The advantage of wood shavings becomes more pronounced under increased stocking densities, where the performance gap between wood shavings and alternatives widens considerably

– Wood shavings deliver superior feed conversion ratios compared to alternative litter materials

General Recommendations for Effective Litter Management

Successful litter management requires adherence to several fundamental principles that promote both bird health and production efficiency:

– Add fresh litter material when litter quality deteriorates

– Maintain „Dry and Friable“ Litter: The primary objective involves providing permanent access to litter that is both dry and friable. This condition prevents health issues such as footpad dermatitis (FPD) while ensuring optimal chicken welfare.

– Avoid Overly Dry and Dusty Conditions: While dry litter is crucial, management must equally prevent conditions that become too dry and dusty. Such environments can lead to respiratory diseases, inflammation, reduced body weight gain, scratches, and skin tears.

– Address Factors Contributing to High Litter Moisture and Caking: Several management practices and facility design features worsen litter moisture and caking, including:

-

- High density at placement (when followed by later unloading of birds)

- Concrete floors

- Pop holes in free-range houses

- Inadequate litter depth

- Floor preheating

- Poor airflow within the houses

The Science and Practice of Litter Turning

Litter turning represents a targeted management intervention designed to restore litter quality through mechanical disruption of caked areas, pulverization of clumps, moisture redistribution, and creation of uniform surface layers. While commonly performed at regular intervals (typically weekly) or in response to visible caking, this practice is generally avoided during the first 14 days of production and may be delayed based on factors such as bird size, flock density, or welfare considerations.

However, litter turning carries inherent risks that demand careful consideration. The mechanical disruption can trigger ammonia and dust surges, increase gaseous emissions, and potentially stimulate blooms of Clostridium bacteria and coccidiosis through increased aeration. The probability and severity of these adverse outcomes depend heavily on existing litter conditions, historical management practices, and the integration of ventilation systems with litter management protocols (Pepper and Dunlop, 2021).

The Ammonia Challenge

Research demonstrates that raking broiler litter significantly elevates ammonia (NH₃) concentrations by approximately 49% compared to undisturbed systems (Brink et al., 2022). This occurs because undisturbed litter develops a compacted surface crust that functions as a physical barrier, inhibiting both ammonia formation and volatilization. Mechanical disruption breaks this protective layer, creating a more aerobic and friable structure that accelerates uric acid and nitrogen conversion to ammonia. The resulting increase in litter pH further promotes ammonia release, creating a self-reinforcing cycle.

Integrated Management Approach

Given these risks, litter turning as an isolated practice proves counterproductive due to excessive ammonia release. Instead, successful implementation requires integration into comprehensive flock management systems following specific protocols:

Complementary Implementation: Litter turning should complement, rather than replace, other management practices. When combined with effective ventilation, it can reduce wet litter and caking while improving friability and supporting drying processes.

Encouraging Natural Behavior: Friable litter allows chickens to naturally „work“ the substrate, incorporating fresh excreta through normal movement patterns. Mechanical turning becomes necessary only when litter loses friability or becomes cohesive.

Systematic Integration: Effective litter management forms part of a broader strategy encompassing ventilation, heating, drinker management, and strategic dry litter supplementation (Dunlop and Pepper, 2023).

Timing and Precautions

Successful litter turning requires careful attention to timing and conditions:

Pre-Turning Assessment: Understanding historical conditions and current litter status is crucial. Drier, friable litter that chickens are actively working typically produces smaller contaminant surges during turning.

During Turning: Operators must prepare for potential surges in ammonia, moisture, heat, pathogens, fungal spores, and other biological contaminants.

Immediate Post-Turning (Several Hours): Continued monitoring and response to potential risks remains essential.

Long-Term Effects (Days to Weeks): Sustained impacts on litter quality and house environment require ongoing evaluation.

Ventilation Readiness: Ventilation systems must be prepared to increase airflow or implement other mitigation measures to counter contaminant surges.

Temperature Considerations: While maximizing water evaporation is desirable, evaporative cooling can reduce litter temperature, potentially affecting young or temperature-sensitive birds (Dunlop and Pepper, 2023).

Benefits of Proper Litter Turning

When executed correctly, litter turning provides several advantages:

Enhanced Moisture Management: Mechanical disruption effectively addresses excess moisture by breaking up caked litter formed through increased particle cohesiveness.

Improved Physical Properties: Machinery provides the energy necessary to overcome tight cohesiveness, reducing bulk density and particle size while increasing flowability and friability.

Optimized Biological Activity: Aeration promotes beneficial aerobic microbial activity, generating heat that facilitates water evaporation and accelerates organic matter decomposition. This process typically produces less odor than anaerobic alternatives, suggesting that maintaining drier, more aerobic conditions reduces long-term odor emissions (Dunlop and Pepper, 2023).

Condition-Specific Outcomes

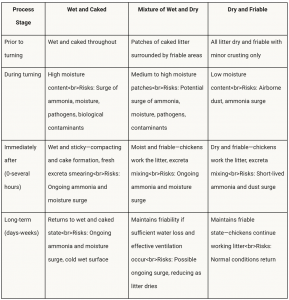

Pepper and Dunlop (2021) provide a comprehensive framework for understanding litter turning outcomes based on initial conditions:

Table 2. Litter turning outcomes based on various starting conditions (Pepper and Dunlop, 2021)

Litter Additives for Ammonia Control

The challenge of ammonia production in poultry litter has driven the development of various additive technologies, each targeting different aspects of the ammonia formation and release process.

1. Acidifiers

These additives reduce litter pH, converting volatile ammonia (NH₃) into non-volatile ammonium (NH₄⁺), thereby reducing airborne ammonia while retaining nitrogen in the litter for enhanced fertilizer value (Tasistro et al., 2007).

Primary acidifiers include:

– Sodium Bisulfate: A dry acid salt that effectively lowers litter pH and can be safely applied with birds present

– Aluminum Sulfate (Alum): Another dry acid salt that reduces pH while binding phosphorus to minimize runoff from land-applied litter

– Sulfuric Acid: Often combined with clay carriers for improved handling

– Citric Acid: A natural acidifier option

2. Alkaline Materials

While less commonly used for active flock ammonia control (as they can increase ammonia release), alkaline materials serve specific purposes in inter-flock management by increasing litter pH above 7. This „cooking off“ process allows ammonia to be vented, resulting in lower ammonia levels when new chicks are placed (Toledo et al., 2020).

Common alkaline materials include:

– Agricultural Lime (CaCO₃)

– Hydrated or Slaked Lime

– Burnt Lime

3. Adsorbers

These materials physically or chemically bind ammonia or absorb moisture, indirectly reducing ammonia volatilization while improving litter dryness (Cook et al., 2011).

Effective adsorbers include:

– Zeolites: Natural minerals with porous structures that trap ammonia molecules

– Diatomaceous Earth: Natural, porous material that absorbs moisture and neutralizes ammonia

– Peat Moss: Capable of adsorbing significant amounts of ammonia and water, though typically more expensive

– Biochar: Emerging technology with promising adsorption properties

4. Inhibitors

These products interfere with biological processes that produce ammonia, targeting the enzymatic pathways responsible for ammonia formation (Singh et al., 2009).

5. Microbial and Enzymatic Treatments

These treatments introduce beneficial microorganisms or enzymes to achieve multiple objectives:

– Promoting competitive exclusion against harmful bacteria

– Breaking down organic matter to potentially reduce ammonia production

– Improving bird gut health when included in feed formulations, though some can be applied directly to litter (Nahm, 2005)

Research-Based Recommendations

Meta-analyses comparing various poultry litter amendments reveal that acidifiers represent the most effective additive category for improving both chicken performance and litter quality (Toledo et al., 2020). Through comprehensive subgroup analysis, researchers found that acidifiers significantly enhance broiler health by reducing litter pH, moisture, ammonia levels, and pathogenic microbiota. These improvements translate directly into enhanced weight gain and decreased mortality rates compared to control groups.

Additional findings include:

– Gypsum demonstrates specific benefits in reducing ammonia and improving feed conversion

– Alkalizing agents prove detrimental, increasing litter pH and broiler mortality while worsening feed conversion, despite reducing litter moisture and pathogenic microbiota

– Superphosphate effectively reduces litter pH

– Adsorbents successfully reduce litter moisture content compared to control groups

Conclusions and Management Recommendations

Maintaining optimal poultry litter conditions requires a multifaceted approach that recognizes the interconnected nature of environmental, biological, and economic factors. Success depends on implementing several key practices as an integrated system rather than isolated interventions.

Core Management Practices:

Regular Litter Maintenance: Systematically remove or turn litter in humid and compacted areas of poultry houses, ensuring that mechanical interventions are properly timed and supported by adequate ventilation.

Quality Sourcing: Source litter materials exclusively from authorized and accredited suppliers to ensure consistent sanitary quality and performance characteristics.

Facility Sanitation: Perform complete washing and disinfection of poultry houses after each litter cycle to prevent pathogen carryover and maintain optimal starting conditions.

Strategic Supplementation: Add fresh, dry material to litter surfaces when significant numbers of animals are introduced or exchanged, maintaining optimal moisture balance and substrate quality.

Environmental Control: Implement effective poultry house ventilation systems that work synergistically with litter management to reduce humidity and support optimal air quality.

Health Monitoring: Continuously monitor birds for foot lesions, recognizing their implications for both economic returns and animal welfare as indicators of litter quality.

Target Characteristics: Strive to maintain litter that is soft, dry, dust-free, absorbent, spongy, and pathogen-free—characteristics that support both bird health and production efficiency.

The economic implications of litter management extend far beyond material costs, encompassing impacts on bird performance, medication requirements, processing quality, and overall farm profitability. As the industry continues to evolve, successful producers will be those who master the complex interplay between litter management, environmental control, and bird welfare to achieve sustainable, profitable operations.

References

Bolan, N. S., Szogi, A. A., Chuasavathi, T., Seshadri, B., Rothrock Jr, M. J., & Panneerselvam, P. (2010). Uses and management of poultry litter. World’s Poultry Science Journal, 66(4), 673-698.

Brink, M., Janssens, G. P., & Delezie, E. (2022). How do moisture content, friability, and crust development of litter influence ammonia concentrations in broiler production? Livestock Science, 265, 105109.

Cook, K. L., Rothrock Jr, M. J., Eiteman, M. A., Lovanh, N., & Sistani, K. (2011). Evaluation of nitrogen retention and microbial populations in poultry litter treated with chemical, biological or adsorbent amendments. Journal of Environmental Management, 92(7), 1760-1766.

Dunlop, M. W., & Pepper, C. M. (2023). Litter management to support chicken meat production and industry growth. Animal Production Science.

Nahm, K. H. (2005). Environmental effects of chemical additives used in poultry litter and swine manure. Critical Reviews in Environmental Science and Technology, 35(5), 487-513.

Pepper, C. M., & Dunlop, M. W. (2021). Review of litter turning during a grow-out as a litter management practice to achieve dry and friable litter in poultry production. Poultry Science, 100(6), 101071.

Sargeant, J. M., Bergevin, M. D., Churchill, K., Dawkins, K., Deb, B., Dunn, J., … & Winder, C. B. (2019). The efficacy of litter management strategies to prevent morbidity and mortality in broiler chickens: a systematic review and network meta-analysis. Animal Health Research Reviews, 20(2), 247-262.

Singh, A., Casey, K. D., King, W. D., Pescatore, A. J., Gates, R. S., & Ford, M. J. (2009). Efficacy of urease inhibitor to reduce ammonia emission from poultry houses. Journal of Applied Poultry Research, 18(1), 34-42.

Tasistro, A. S., Ritz, C. W., & Kissel, D. E. (2007). Ammonia emissions from broiler litter: response to bedding materials and acidifiers. British Poultry Science, 48(4), 399-405.

Toledo, T. D. S. D., Pich, C. S., Roll, A. A. P., Dai Prá, M. A., Leivas Leite, F., Gonçalves Xavier, E., & Roll, V. F. B. (2019). The effect of litter materials on broiler performance: a systematic review and meta-analysis. British Poultry Science, 60(6), 605-616.

Toledo, T. D. S., Roll, A. A. P., Rutz, F., Dallmann, H. M., Dai Pra, M. A., Leite, F. P. L., & Roll, V. F. B. (2020). An assessment of the impacts of litter treatments on the litter quality and broiler performance: A systematic review and meta-analysis. PLoS One, 15(5), e0232853.