Why Chicken Growth Rates Determine Your Feed Budget Success

Feed represents 70% of all production costs in broiler growth operations (Tandoğan & Çiçek, 2016). Every gram of weight gain efficiency directly impacts profitability. Research shows that a 2% increase in coefficient of variation (CV) leads to a 0.3-point decline in feed conversion ratio (FCR) (Vasdal et al., 2019). This means birds consume an additional 0.3 kg of feed to gain the same 1 kg of weight.

The difference between profitable and struggling operations often comes down to how precisely they track chicken growth patterns and respond to deviations. Professional producers using systematic weighing protocols consistently achieve better uniformity and lower feed conversion ratios.

What Are the Broiler Feeds at Different Stages of Growth: The Economics Behind Timing

Understanding feed conversion efficiency requires tracking performance at each growth phase. According to Lukić et al., the follow approach yields the best results:

Starter Phase (0-7 days): Target FCR of 1.05-1.14 kg feed per kg gain. Early precision in this phase sets the foundation for the entire production cycle.

Extended Starter (0-21 days): Aim for FCR between 1.32-1.38. Deviations here multiply throughout the remaining growth period.

Grower Phase (22-35 days): FCR typically ranges 1.68-1.75. This phase shows significant response to management interventions.

Finisher Phase (36-42 days): Final FCR targets of 1.72-1.76 determine overall profitability. Late corrections become increasingly expensive.

Precise timing of feed transitions based on actual weight data rather than calendar dates can improve overall FCR by 3-5%.

The Uniformity Factor

Flock uniformity directly correlates with profitability. Research demonstrates clear relationships between uniformity metrics and economic performance:

Coefficient of Variation Targets: CV of 8% or less indicates excellent uniformity. CV above 10% signals poor uniformity requiring immediate management intervention.

Uniformity Percentages: Target 70-72% uniformity under normal management conditions. Well-managed flocks can achieve 80% uniformity by photostimulation timing.

Standard Deviation Applications: This overlooked metric helps estimate bird distribution within weight ranges, supporting processing planning and market timing decisions.

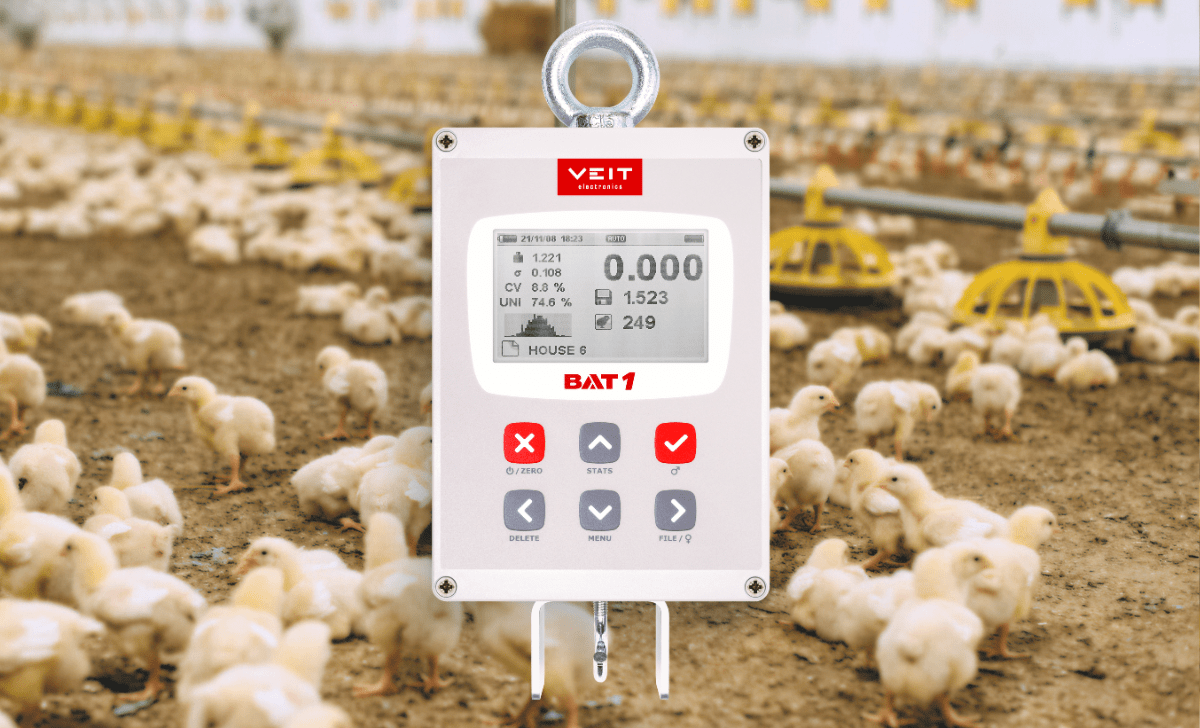

The BAT1 manual poultry scale automatically calculates these critical statistics, eliminating calculation errors and providing immediate feedback for management decisions.

Sampling Protocols That Deliver Reliable Broiler Chicken Growth Chart Data

Accurate growth monitoring requires systematic sampling approaches validated by research:

Sample Size Requirements: Weigh minimum 1-2% of population or 50-100 birds, whichever is greater (Hughes & Wilkinson, 2017). Larger flocks require proportionally larger samples for statistical accuracy.

Age-Specific Protocols: Birds 0-21 days can be weighed in groups using catching frames. Birds over 21 days require individual weighing for accuracy (Lingens et al., 2021).

Location Strategy: Collect samples from three house locations (front, middle, back) avoiding areas near feed hoppers where birds tend to be heavier than average (Cobb Breeder Management Guide).

Frequency Standards: Weekly weighing provides baseline monitoring. Twice-weekly weighing during final growth phases enables precise processing timing decisions.

Research using BAT1 chicken scales demonstrated that 1.4-1.5% sample size provides sufficient accuracy for reliable average weight determination in commercial flocks.

Technology Integration for Poultry Weighing Scale Optimization

Modern poultry weighing scale systems transform raw data into actionable intelligence:

Automatic Calculations: Professional scales calculate average weight, uniformity percentage, CV, and standard deviation eliminating human calculation errors.

Data Storage Capacity: Systems storing thousands of individual weights across multiple groups enable trend analysis and performance comparisons.

Software Integration: Direct data transfer to farm management systems eliminates transcription errors and enables immediate analysis.

Real-time Monitoring: Instant access to growth statistics supports rapid management responses to deviation patterns.

The BAT1’s internal memory and automatic timestamping removes opportunities for data falsification while ensuring complete record keeping for analysis.

Converting Chicken Growth Data Into Feed Efficiency Gains

Professional producers achieve superior results by systematically analyzing weight data:

FCR Monitoring: Track conversion ratios by growth phase. Early detection of efficiency problems enables corrective action before significant economic impact.

Growth Rate Analysis: Monitor weekly weight gains against breed standards. Deviations exceeding 5% warrant investigation into feed quality, distribution, or environmental factors.

Uniformity Tracking: Poor uniformity indicates management problems requiring immediate attention. Consistent monitoring enables proactive rather than reactive management.

Historical Comparisons: Database records enable seasonal pattern identification and year-over-year performance improvements.

Economic Impact of Precision Weighing

Investment in professional weighing equipment delivers measurable returns:

Feed Efficiency Improvements: Systematic monitoring typically yields 3-8% improvements in feed conversion efficiency.

Processing Optimization: Accurate weight prediction enables optimal processing timing, maximizing carcass value.

Reduced Variability: Improved uniformity reduces processing downgrades and increases product value.

Labor Efficiency: Streamlined data collection and calculation reduces labor requirements while improving accuracy.

Implementation Strategy for Broiler Growth Optimization

Start implementing precision weighing protocols immediately:

Equipment Selection: Choose scales with 1-gram accuracy and automatic data recording capabilities. The BAT1 provides professional-grade accuracy with user-friendly operation.

Protocol Development: Establish consistent sampling procedures, timing, and location protocols. Train staff on proper techniques and equipment calibration.

Data Management: Implement systems for data storage, analysis, and trend monitoring. Integrate weighing data with other production metrics.

Performance Monitoring: Establish baseline performance metrics and track improvements over time.

Ready to transform your chicken growth monitoring into profit optimization? Professional weighing equipment pays for itself through improved feed efficiency and reduced waste. Visit https://poultryscales.com/bat1 to discover how the BAT1 can optimize your growth curve management.

Cited Sources

- Cobb Breeder Management Guide. Page 75-79. Weight calculation and uniformity analysis protocols.

- Lingens, J.B., et al. (2021). Sample size optimization for reliable broiler growth monitoring using BAT1 manual poultry scales. Research study on Ross 308 chickens, groups 3,318-3,582 birds.

- Tandoğan, M., & Çiçek, H. (2016). Economic impact of feed conversion efficiency in commercial broiler production. Feed costs representing 70% of total production expenses.

- Vasdal, G., et al. (2019). Relationship between flock uniformity and feed conversion ratio. Research demonstrating 2% CV increase correlates with 0.3-point FCR decline.

- Lukić, M., et al. (2022). How does the choice of genotype and feed in the local market affect broiler performance and farm economy? Agriculture Journal, 12, 843.