The future of poultry farming lies in precision. Smart poultry farm technology has moved beyond concept to reality, transforming how farmers manage their operations. This shift represents more than just adding gadgets to barns. It means reclaiming valuable time while boosting productivity through data-driven decisions.

The Smart Revolution in Poultry Houses

IoT based smart poultry farm systems are changing the game. These networks connect sensors, automated feeders, and monitoring devices into one seamless operation. Farmers can now track everything from feed consumption to bird weight gain in real time.

Consider this: traditional farms can lose 15-20% or more of their potential profit due to inefficient monitoring. Smart harvest poultry farming eliminates this waste by providing instant alerts when conditions change.

Modern poultry farming technology includes automated weighing systems that work around the clock. Birds step onto scales naturally, creating continuous weight data without human intervention. This constant monitoring helps farmers spot health issues early and immediately adjust feed programs, as well as other environmental factors.

Weight Management: The Foundation of Success

Accurate weight tracking drives every successful poultry operation. New technology in poultry production has made this process both simpler and more precise. Automated systems eliminate human error while providing detailed analytics that manual methods cannot match.

Research shows birds following optimal weight curves produce more eggs per hen over their lifetime. The BAT Sorting Machine exemplifies this precision approach. This innovative system works with existing BAT1 manual scales to automatically sort birds into weight categories, saving hours of manual labor while enhancing uniformity.

Data Integration Transforms Decision Making

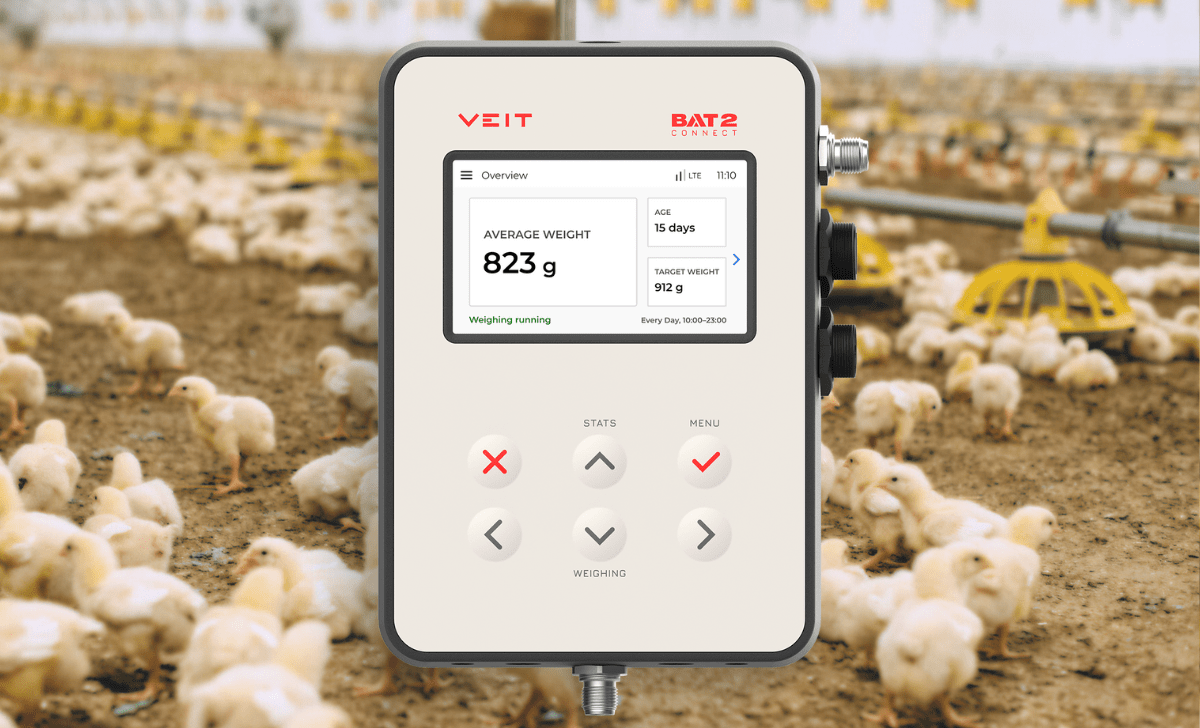

The most successful IoT poultry operations share one trait: seamless data integration. Modern systems connect weight data from specialized automatic scales like the BAT2 Connect, environmental sensors, and feed consumption into unified dashboards. Farmers access this information from their computers or even their phones, making informed decisions from anywhere.

This connectivity proves especially valuable during critical growth periods. When week 16-20 birds show weight deviations, immediate adjustments can extend peak production by three weeks.

Real-World Implementation

Implementing smart poultry farm technology doesn’t require replacing entire operations overnight. Many farmers start with automated weighing systems, then gradually add sensors and monitoring equipment.

The BAT Sorting Machine demonstrates this practical approach. It integrates with existing equipment while providing immediate benefits. Farmers report saving 2-3 hours daily on sorting tasks, time they can invest in other management activities.

Looking Forward

Precision agriculture in poultry farming continues to evolve. New technology in poultry production focuses on predictive analytics, helping farmers anticipate problems before they occur. This proactive approach represents the next phase of smart farming.

The investment in technology used in poultry farming pays dividends through improved efficiency, reduced labor costs, and better bird performance. Most importantly, it gives farmers back their time while maintaining the highest standards of animal care.

Success in modern poultry farming demands embracing these technological advances. The farms implementing IoT based smart poultry farm systems today will lead the industry tomorrow.